PSE-Lab contributed to conceptualizing and developing the Plant Simulator since 2007 within the EC 6FP Virthualis project and the following Virthualis.com spin-off support.

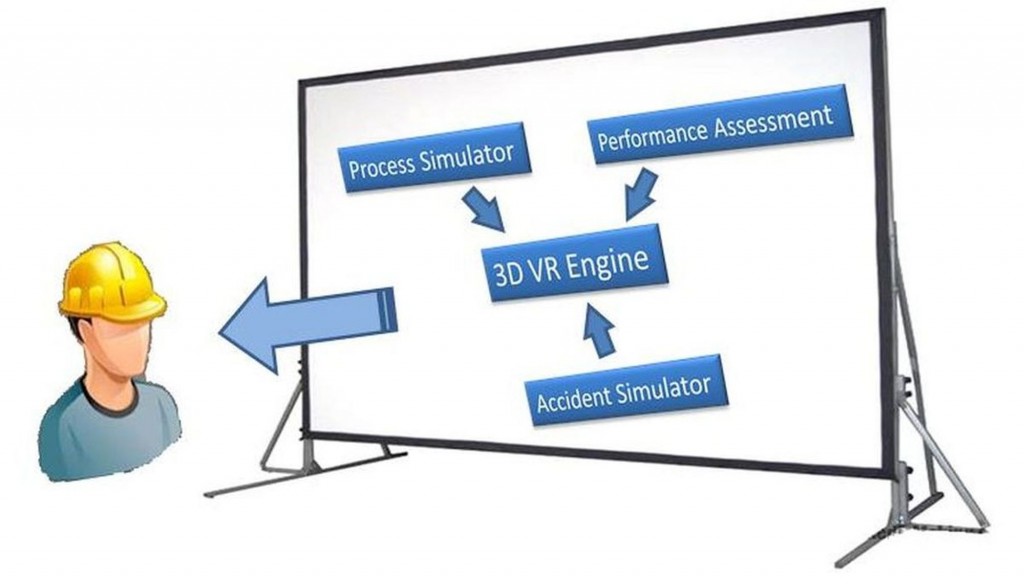

The Plant Simulator consists of coupling a conventional OTS (i.e. Operator Training Simulator) with an Immersive Virtual-Reality Environment (IVE) (commonly referred to as a 3D environment) that simulates the field in all its facets comprising spatial sound (commonly referred to as 3D sound). The Plant Simulator makes interacting in real-time three programs: a dynamic process simulator, a dynamic accident simulator (©AXIM), and a performance assessment algorithm (©Performex).

The core benefit of this solution, which is also a breakthrough with respect to conventional training solutions, is that the data exchange between the process simulator and the accident simulator allows:

• tracking the dynamic evolution of the process when an accident occurs;

• quantifying the possible effects and damages on the structures and the equipment;

• quantifying the potential injuries that field operators would suffer in real life.

In addition, the constructs from Human Factors research are also integrated into the Plant Simulator. For instance, use of 3D environment which facilitates spatial and immersive learning. The Plant Simulator allows simulating various normal and abnormal situations, where trainees can practice and enhance their skills, which are necessarily required for normal operating conditions as well as for abnormal situation management. A conceptual representation of the Plant Simulator is shown below:

Â