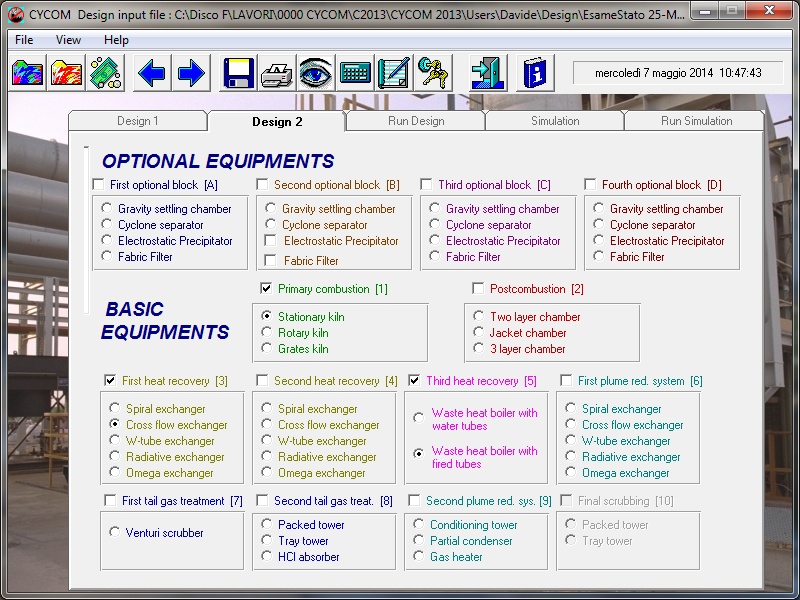

CYCOM is a computer program for the Design and Simulation of Incineration Plants.

CYCOM has been adopted by a number of engineering companies and incineration plants to respectively design the equipment and simulate the operations of incineration plants.

Contrary to other process simulators, CYCOM allows designing the single process units and the plant layout by assigning the exact design specifications. Instead of asking the user to work with a trial-and-error approach, the user assigns the design specifications and CYCOM determines the geometric features of the equipment.

Once the process units are geometrically dimensioned, then the user can modify some input data and run the Simulation procedure to see how the plant reacts to external disturbances. Both geometry and input streams can be imported from the Design procedure by means of a click (on the blue right-arrow button in the above image) then modified in the Simulation procedure and simulated accordingly.

A detailed report of the process units and the plant features is finally provided.

Both Design and Simulation procedures are based on detailed first principle models with material, energy and momentum equations solved with advanced numerical algorithms specifically tailored for robustness convergence and CPU efficiency with the incineration target in mind.

This is a schematic representation of CYCOM features:

- Input streams

- Waste characterization

- Elementary analysis

- Data base of chemical substances

- Dust granulometric distribution

- Waste characterization

- Combustion chambers

- Drums and Grates kilns

- Rotary kilns

- Stationary kilns

- Postcombustion chambers

- Heat exchangers

- Waste heat boilers

- Tail gas treatment systems

- Gas-solid separators

- Gravity settling chambers

- Cyclone separators

- Electrostatic precipitators

- Fabric filters